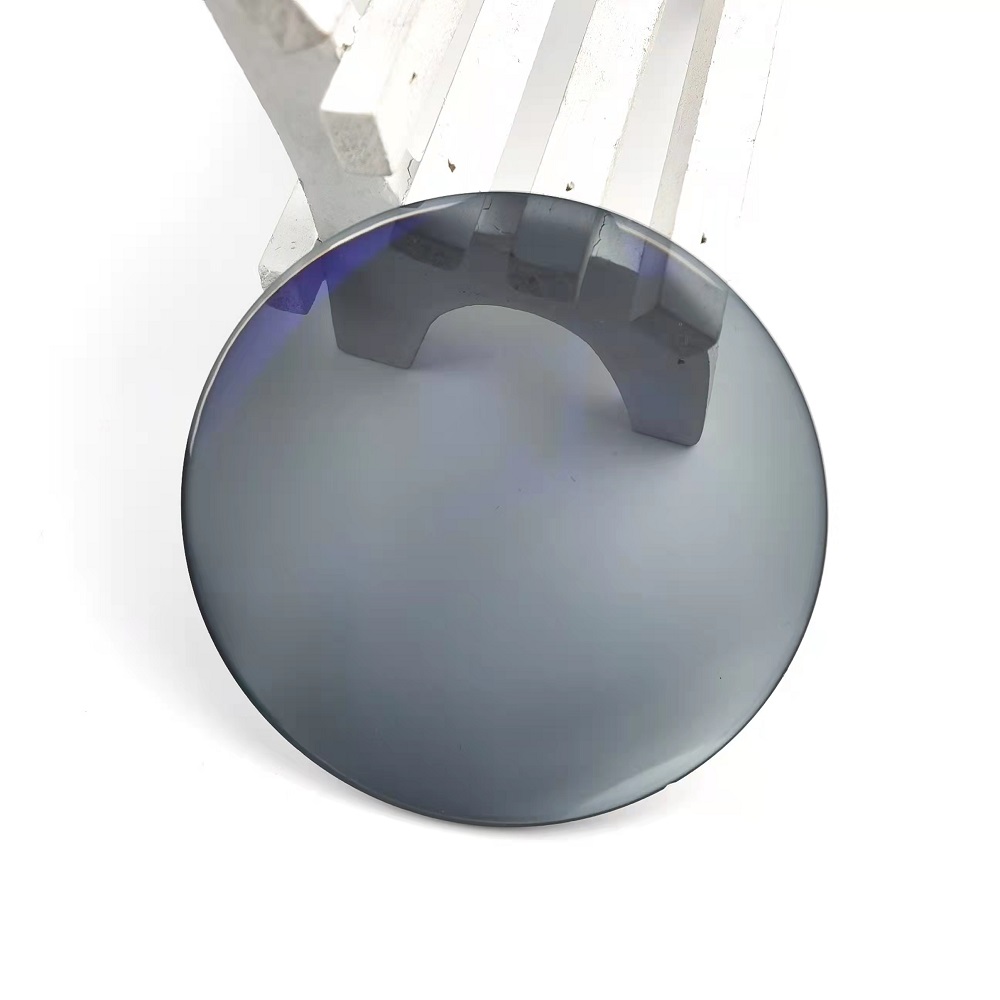

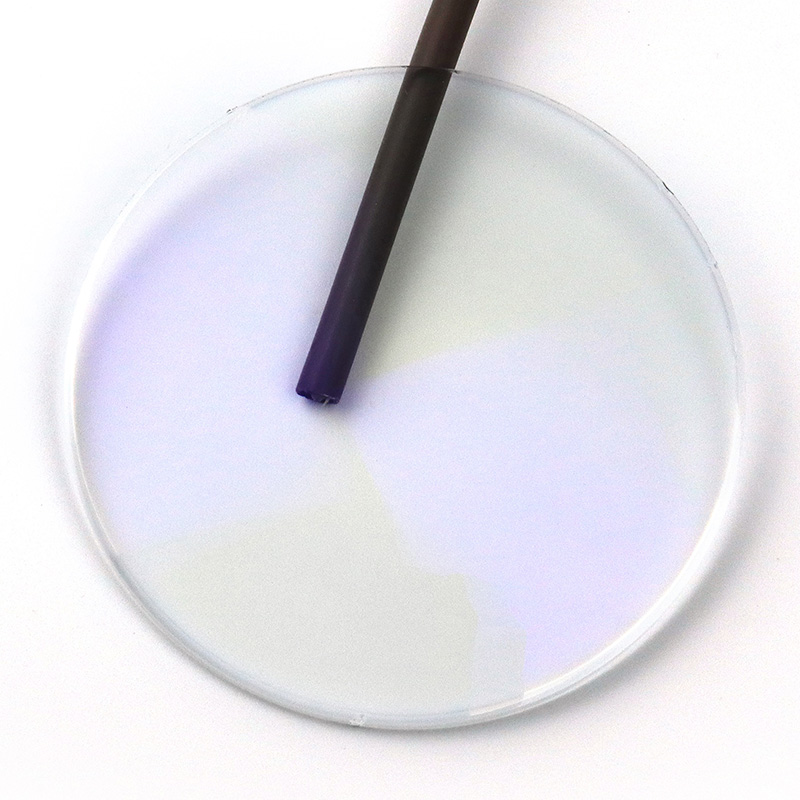

I-SETO 1.60 iLens Photochromic SHMC

Inkcazo

| I-1.60 i-photochromic shmc lens optical | |

| Umzekelo: | 1.60 ilensi yamehlo |

| Indawo yemvelaphi: | Jiangsu, China |

| Uphawu: | SETO |

| Izinto zeeLensi: | Intlaka |

| Umbala weeLensi: | Cacileyo |

| Refractive Index: | 1.60 |

| Ububanzi: | 75/70/65 mm |

| Umsebenzi: | photochromic |

| Ixabiso le-Abbe: | 32 |

| Ubunzima obuthile: | 1.26 |

| Ukhetho loKutyabeka: | HMC/SHMC |

| Umbala wokwaleka | Luhlaza |

| Uluhlu lwamandla: | Sph:0.00 ~-10.00;+0,25 ~ +6.00;Cyl:0.00~ -4.00 |

Iimpawu zeMveliso

1) Yintoni i-spin coating?

I-Spin coating yinkqubo esetyenziselwa ukufaka iifilim ezibhityileyo ezifanayo kwiisubstrate ezisicaba.Ngokuqhelekileyo umthamo omncinci wezinto zokugquma usetyenziswa kumbindi we-substrate, onokuthi ujikeleze ngesantya esiphantsi okanye ungajikelezi kwaphela.I-substrate ke ijikelezwe ngesantya ukuya kwi-10,000 rpm ukusasaza izinto zokugquma ngamandla e-centrifugal.Umatshini osetyenziselwa ukujikeleza ubizwa ngokuba yi-spin coater, okanye ngokulula i-spinner.

Ukujikeleza kuyaqhubeka ngelixa ulwelo lujikeleza emaphethelweni e-substrate, de kube ubuninzi obufunwayo befilimu bufezekisiwe.I-solvent esetyenzisiweyo idla ngokuguquguquka, kwaye ngaxeshanye ikhuphe.Ukuphakama kwesantya se-angular sokujikeleza, ifilimu iyancipha ngakumbi.Ubukhulu befilimu bukwaxhomekeke kwi-viscosity kunye nokugxila kwesisombululo, kunye ne-solvent.Uhlalutyo lwethiyori yobuvulindlela ye-spin coating lwenziwa ngu-Emslie et al., kwaye iye yandiswa ngababhali abaninzi abalandelayo (kubandakanya uWilson et al., [4] abafunde izinga lokusasazeka kwi-spin coating; kunye no-Danglad-Flores et al., [5] ngubani ofumene inkcazo yendalo yonke ukuqikelela ubungakanani befilimu efakiweyo).

I-Spin yokwambathisa isetyenziswa ngokubanzi kwi-microfabrication ye-oxide esebenzayo umaleko kwiglasi okanye kwi-crystal substrates enye usebenzisa i-sol-gel precursors, apho ingasetyenziselwa ukwenza iifilimu ezibhityileyo ezifanayo ezinobunzima be-nanoscale.[6]Isetyenziswe kakhulu kwi-photolithography, ukubeka iileyile ze-photoresist malunga ne-1 micrometer ubukhulu.I-Photoresist ngokuqhelekileyo iphothwa ku-20 ukuya kwi-80 revolutions ngomzuzwana kwimizuzwana engama-30 ukuya kuma-60.Ikwasetyenziswa ngokubanzi ukwakhiwa kwezakhiwo zefotonic ezicwangcisiweyo ezenziwe ngeepolymers.

Enye inzuzo yokujikeleza iifilimu ezibhityileyo kukufana kobunzima befilimu.Ngenxa yokuziphakamisa, ubukhulu abuhlukanga ngaphezu kwe-1%.Nangona kunjalo, iifilimu ezishinyeneyo zokugquma iipolymers kunye neefotoresists zinokubangela amaso amakhulu omphetho anokucwangciswa kwawo kunemida yomzimba.

2) Isebenza njani iSpin Coating?

Le nkqubo isebenza ngokulawula ngononophelo isantya ngokumalunga neempawu zezinto ezahlukeneyo zesisombululo.I-Viscosity yeyona nto iphambili phakathi kwezi mpawu njengoko imisela ukuxhathisa ukuhamba okufanayo, okubalulekileyo ekufezekiseni umphezulu ofanayo.I-Spin coating iqhutywa emva koko kuluhlu lwesantya esibanzi kakhulu, ukusuka kancinci ukuya kuma-500 revolutions ngomzuzu (rpm) ukuya kuthi ga kwi-12,000 rpm - kuxhomekeke kwi-viscosity yesisombululo.

I-Viscosity ayisiyiyo kuphela ipropati yezinto ezinomdla kwi-spin coating, nangona kunjalo.Ukuxinana komphezulu kunokuchaphazela iimpawu zokuhamba kwesisombululo, ngelixa iipesenti eziqinileyo zinokuchaphazela ubungakanani befilimu efunekayo ukuze kuphunyezwe iimpawu ezithile zokusetyenziswa kokuphela (okt ukushukuma kombane).I-Spin coating iqhutywa emva koko ngokuqonda ngokupheleleyo izinto ezifanelekileyo eziphathekayo, kunye neeparitha ezininzi ezinokuhlengahlengiswa ukuze zihambelane neempawu ezahlukileyo (ukuhamba, i-viscosity, ukumanzi, njl.).

I-Spin coating inokuqhutywa kusetyenziswa isiqalo esimileyo okanye esiguqukayo, nganye apho inokucwangciswa kumsebenzisi-echazwe ngumsebenzisi wokunyuka kwesantya kunye nezantya ezahlukeneyo zokujikeleza.Kukwabalulekile ukuvumela amaxesha okukhupha umsi kunye namaxesha okomisa njengoko ukungangeni komoya okungalunganga kunokukhokelela kwiziphene zamehlo kunye nokungafaniyo.Umzekelo: Iipateni ze-Swirl zingabonisa ukuba isantya sokukhupha siphezulu kakhulu kwisisombululo esithatha ixesha elide ukuba some.Akukho sicombululo sobukhulu obunye xa sifika kwi-spin coating, kwaye inkqubo nganye kufuneka iqhutywe ngendlela epheleleyo kwi-substrate kunye nesisombululo sokugubungela umbuzo.

3) UKhetho lweCoating?

Njengoko 1.60 Photochromic Lens SHMC, super hydrophobic ukutyabeka kuphela ukhetho ukutyabeka kuyo.

I-Super hydrophobic coating ikwabizwa ngokuba yi-crazil coating, inokwenza iilensi zingangeni manzi, i-antistatic, i-anti slip kunye nokumelana neoli.

Ngokubanzi, i-super hydrophobic coating ingabakho kwiinyanga ezi-6 ~ 12.

Isiqinisekiso

Umzi-mveliso wethu